leeb rebound hardness test principle|bounce ball hardness testers : factories The traditional methods are based on well-defined physical indentation hardness tests. Very hard indenters of defined geometries and sizes . See more The central processing area (s) ideally should be divided into at least three areas: decontamination, packaging, and sterilization and storage. Physical barriers should separate .

{plog:ftitle_list}

ACI 523.4R-09 Reported by ACI Committee 523 Guide for Design and Construction with Aut.

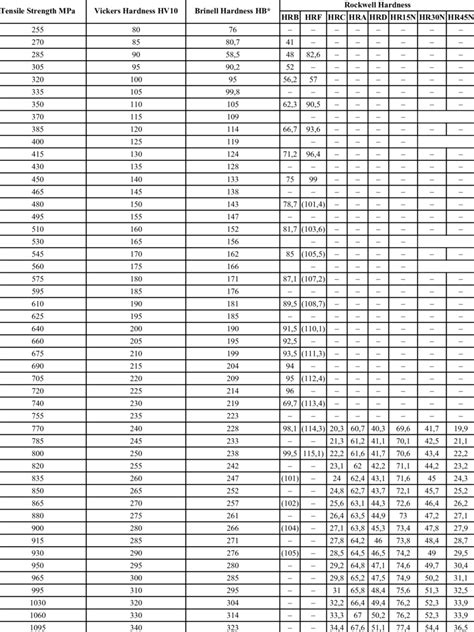

leebs hardness chart

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg). It measures the coefficient of restitution. It is a form of . See moreThe Equotip (later on also called simultaneously as Leeb method) rebound hardness test method was developed in the year 1975 by Leeb and Brandestini at Proceq SA to . See more• German standards and specifications:• American standards:• Official international standards projects:• Official . See more

• http://grhardnesstester.com/blog/methods-testing-hardness-steel/• https://www.baq.de/template.cgi?page=service_infos_ueber_messverfahren&rubrik=&id=&lang.The traditional methods are based on well-defined physical indentation hardness tests. Very hard indenters of defined geometries and sizes . See more

basket centrifuge

Depending on the probe (“impact device”) and indenter (“impact body”) types that vary by geometry, size, weight, material and spring force, . See more• Meyer hardness test See more

Using an ultrasonic hardness tester, the Leeb Rebound tester can inspect the parts below 2mm (0.11″) supported or combined with a heavier .Another well-known principle for portable hardness testers is the rebound method. The DynaMIC and DynaPOCKET (Krautkramer), for example, measure the velocity of a propelled impact . The core principle of the Leeb method revolves around measuring energy loss. During the test, an impact body strikes the metallic surface. The resulting loss of energy due to material deformation is meticulously measured, .

The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to . The Leeb hardness test (LHT with test value of L D ) is a rebound hardness test, originally developed for metals, that has been correlated with the Unconfined Compressive . The Leeb hardness number (L) is calculated from the ratio of the rebound velocity to the impact velocity of a spherically shaped tungsten carbide, silicon nitride, or diamond .

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for .

Using an ultrasonic hardness tester, the Leeb Rebound tester can inspect the parts below 2mm (0.11″) supported or combined with a heavier part or up to any thickness; Measure the .The Leeb method principle uses a spherical tungsten carbide ball and a spring load to measure the hardness of a test piece. This method uses a rebound technique which measures the .Another well-known principle for portable hardness testers is the rebound method. The DynaMIC and DynaPOCKET (Krautkramer), for example, measure the velocity of a propelled impact . The core principle of the Leeb method revolves around measuring energy loss. During the test, an impact body strikes the metallic surface. The resulting loss of energy due to .

The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to . The Leeb hardness test (LHT with test value of L D ) is a rebound hardness test, originally developed for metals, that has been correlated with the Unconfined Compressive .

The Leeb hardness number (L) is calculated from the ratio of the rebound velocity to the impact velocity of a spherically shaped tungsten carbide, silicon nitride, or diamond .Principle. The Leeb hardness test defines the hardness HL as the quotient of the velocities before and after the impact of a well-defined impact body (mostly with a spherical contact area) and a .

leeb rebound hardness test wikipedia

leeb hardness tester principle

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for .

Using an ultrasonic hardness tester, the Leeb Rebound tester can inspect the parts below 2mm (0.11″) supported or combined with a heavier part or up to any thickness; Measure the .The Leeb method principle uses a spherical tungsten carbide ball and a spring load to measure the hardness of a test piece. This method uses a rebound technique which measures the .Another well-known principle for portable hardness testers is the rebound method. The DynaMIC and DynaPOCKET (Krautkramer), for example, measure the velocity of a propelled impact . The core principle of the Leeb method revolves around measuring energy loss. During the test, an impact body strikes the metallic surface. The resulting loss of energy due to .

The Leeb hardness test is of the dynamic or rebound type, which primarily depends both on the plastic and on the elastic properties of the material being tested. The .Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to .

The Leeb hardness test (LHT with test value of L D ) is a rebound hardness test, originally developed for metals, that has been correlated with the Unconfined Compressive . The Leeb hardness number (L) is calculated from the ratio of the rebound velocity to the impact velocity of a spherically shaped tungsten carbide, silicon nitride, or diamond .

inline centrifugal fan

Parker Autoclave's SW Series needle valves are designed as a high flow, non-rotating rising stem valve, with working pressures to 15,000 psi (1034 bar). The Parker Autoclave tubing sizes .

leeb rebound hardness test principle|bounce ball hardness testers